Short Description

A steam trap is a type of automatic valve used in steam systems to discharge condensate, air, and non-condensable gases without losing live steam.

It ensures that steam systems operate efficiently by maintaining proper heat transfer and preventing water hammer or equipment damage. Steam traps work automatically based on differences in temperature, density, or pressure between steam and condensate.

Key Features

- Automatically discharges condensate and air from steam lines

- Prevents loss of live steam, improving energy efficiency

- Protects equipment from water hammer and corrosion

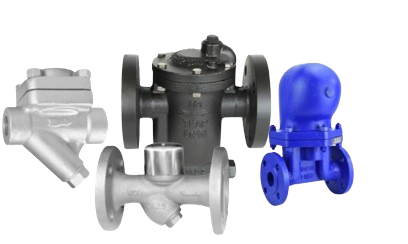

- Available in different types: Thermodynamic, Mechanical (Float & Inverted Bucket), and Thermostatic

- Compact design with high reliability

- Low maintenance and long service life

- Suitable for various steam pressures and capacities

Material Components

- Body : Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel

- Cover / Cap : Carbon Steel, Stainless Steel

- Valve Seat & Disc : Stainless Steel, Alloy Steel (hardened for durability)

- Float / Bucket (for mechanical type) : Stainless Steel

- Thermostatic Element (for thermostatic type) : Stainless Steel or Bimetallic Material

Gasket / Seal : Graphite, PTFE, or Metal-to-Metal

Specifications

- Size Range : ½” – 2” (DN15 – DN50)

- Pressure Rating : Up to Class 900 (PN10 – PN160) depending on type

- Temperature Range : Up to 450°C (depending on body material)

- Connection Ends : Threaded (NPT/BSP), Socket Weld, Butt Weld, Flanged

- Types of Steam Traps :

- Thermodynamic Steam Trap → simple, compact, suitable for high pressure

- Float Steam Trap → continuous discharge, good for large condensate loads

- Inverted Bucket Steam Trap → robust, resistant to wear, long service life

- Thermostatic Steam Trap → temperature-sensitive, good for air removal

- Standards :

-

- Design & Manufacture: ASME / ISO

- Testing: API 598 / ISO 5208

- Flange Standard: ASME B16.5 / EN 1092